|

CL 75 - 560.580,00 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Motor |

|

||

|

Kapacitet rezervoara | 2,1 L | ||

|

Prenos | Hidrostatik | ||

| Vuča | 2 WD | |||

|

Kosište | Izbacivanje trave pozadi sa prednjim otvorom | ||

| Širina otkosa | 75 cm, nož sa plivajućim oštricama otpornim na udarce | |||

| Visina košenja | Od 5 do 15 cm kontinuirano i brzo podesivo pomoću ručice | |||

| Periferna brzina sečiva | 74 m/s | |||

|

Zaključavanje diferencijala | Ručno aktivirano zaključavanje diferencijala | ||

|

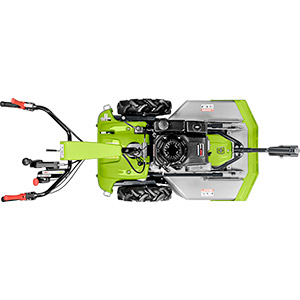

Točkovi | Traktor 4.00-8 četvoroslojne, prednji točkak otporan na probijanje 8x3.00-4 | ||

| Brzina | Kontinuirano promenljiva od 0 to 6 km/h, rikverc od 0 do 3,5 km/h | |||

| Parking kočnica | Aktivacija pedalom | |||

| Rukohvati | Brzo podešavanjem visine i bočno podešavanje upravljača | |||

|

Kapacitet košenja po satu (indikativno) | 2500 m^2/h | ||

|

Dužina | 2150 mm | ||

Širina |

845 mm | |||

| Visina | 1050 mm | |||

|

Težina | 140 kg |

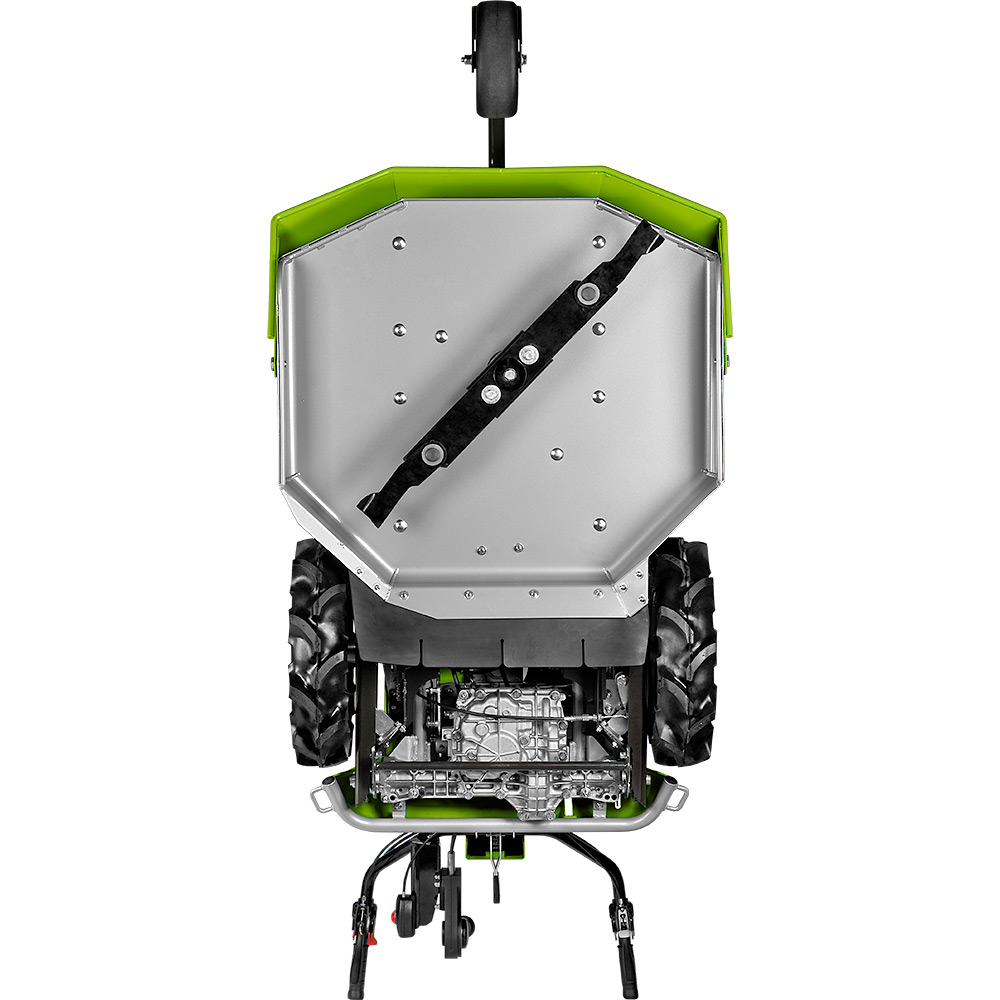

Thanks to the CL 75’s maneuverability, cutting high grass and other vegetation becomes quick and efficient. Uneven ground, steep slopes and different types of obstacles do not present a problem for the CL 75!. The perfect weight distribution and the special tractor tyres give great adherence to the ground under all conditions. The cutter deck has a single blade with swinging tips, producing a very good finish even when mowing grass, making it an ideal machine for grass care both for the professional or domestic user. |

| The deck of the CL 75 is mounted at the front therefore allowing the operator to cut under low positioned branches or bushes. High grass, coppices and bushes are guided into the cutter deck and cut by the blade with (shock-resistant) swinging tips which are made from special steel, the cut material is then discharged out of the rear. If necessary the cutter deck’s front aperture will lift up automatically when entering high vegetation without crushing in down, which considerably increases the efficiency of the machine. |

|

|

The deck is completely made of steel, the cutting height can be adjusted from a minimum of 50mm up to a maximum 150 mm. The adjustment is progressive and can easily be regulated by means of a hand wheel. The cutter deck is kept parallel to the ground in all positions. The cutter decks blade tips are produced with a special profile to reduce noise and produce an excellent quality cut even on English lawns!

The 150 mm maximum cutting height is ideal especially when the ground is very uneven and also to avoid striking the soil. The deck’s front wheel is made of solid rubber, i.e. puncture-proof! |

CL 75 has a perfect weight distribution and a low centre of gravity. The result is perfect balance!

It is possible to use the handlebar with one hand whilst working; this allows the adjustment of the drive and engagement of the reverse gear by a simple lever. When cutting on slopes, near trees and obstacles or if you are cutting in coppices and bushes near low branches, adjusting the grass cutter’s drive so easily turns out to be a very useful addition! |

|

|

The handlebar of the CL 75 has a double adjustment device, ie. height adjustment, in order to meet the operators’ requirements, and lateral adjustment to make cutting easier in difficult areas such as under low positioned branches or in the presence of obstacles.

Also under extreme conditions such as a very steep slope or uneven ground, mowing is easy thanks to the 4 ply wheels mounted on ball bearings and equipped with differential lock. |

The CL 75’s transmission is hydrostatic with differential lock. It is possible to adjust the speed progressively by means of a lever on the handlebar from 0 to 6 km/h and in reverse gear up to 3,5 km/h.

The CL 75 has parking brake enabling you to keep the machine stable even on slopes. All controls are in a comfortable position including the handlebar adjusting levers. |

|

|

The CL 75 is powered by a Honda GXV390 OHV petrol engine with integrated fuel tank having 2,1ltrs capacity. The single cylinder engine has a displacement of 389cc and features all the latest innovations, giving great reliability, low emissions, reduced consumption, high performance and vibration reduced to the minimum, The engine’s manual recoil start is easy and reliable thanks to the particular design of the camshaft, which, during start-up, opens the exhaust valve slightly. The engine is equipped with a lubrication pump allowing the machine to work on slopes without damaging the engine itself. |

The CL 75 can be easily be stood in a vertical position by simply placing the handlebar on the ground. Maintenance and cleaning of the cutter deck is then easily achieved.

|

|

|

|

The CL75, as with all Grillo products, was designed and built to last plus retain its value over many years. All Grillo machines are distributed and serviced by a widespread dealer network. Spare parts remain available for many years after production has stopped giving you extra confidence in Grillo. |

.jpg)